Automotive

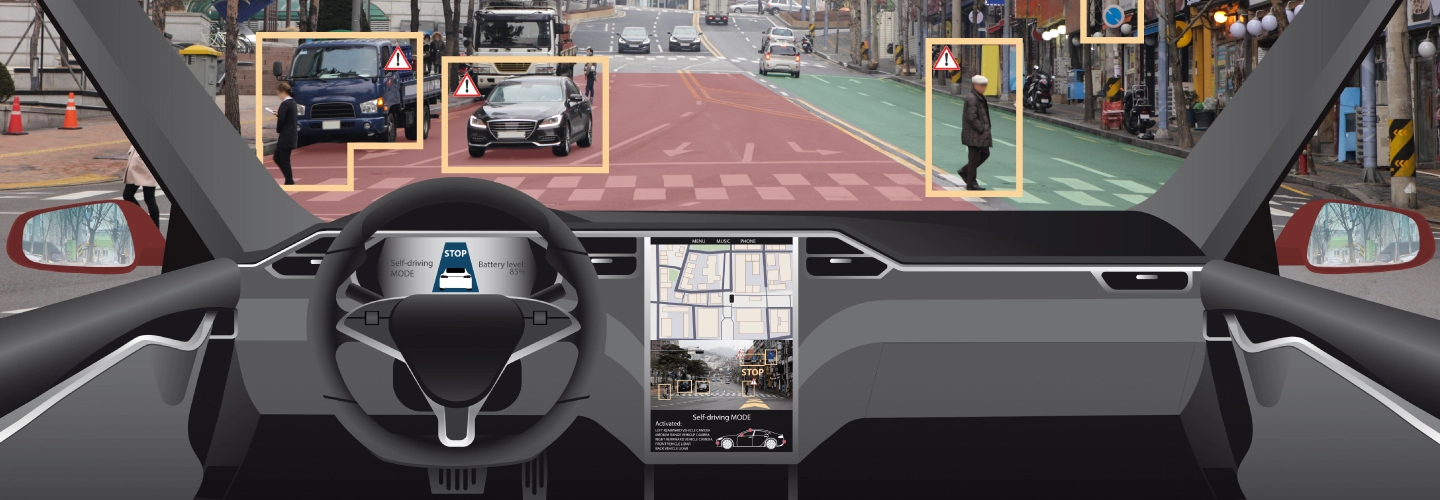

We are witnessing a massive ecosystem transformation in automotive product engineering. Software is increasingly playing a critical role, defining, controlling, and driving the different aspects of vehicle operation. The evolving paradigm, shaping the future of mobility, includes ensuring enhanced safety, improving performance, and enabling a redefined user experience.

As a result, the global automotive industry is being transformed, with a focus on leveraging a centralized, high-performance compute system, with zone- (or domain-controller)-based architectures, helping realize the future of software-defined vehicles (SDVs).

Leveraging a combination of in-depth automotive engineering experiences across vehicle electrification, autonomous drive, connected mobility, and vehicle engineering, combined with our wide range of innovative mobility solutions, LTTS is enabling global customers drive the next wave of mobility. Our global teams work with some of the largest auto manufacturers, OEMs, and Tier 1s to address existing challenges, unlock new opportunities, and drive robust value paradigms across the automotive lifecycle journey.

Leading Lab Infrastructure

Electric Vehicle Lab

Innovation design center for engineering and testing of next-gen electric vehicle components and systems

5G Lab

Focused on for 5G development, NFV Benchmarking, Validation, and Design services

IOT Lab

A place where IoT solutions come to life- from connected workers to smart fuel dispensers, predictive analytics and industrial cybersecurity

Factory Next Lab

Focused on engineering solutions for manufacturing operations management

Teardown & Product Engineering Lab

Value Engineering & and Value Analysis Center focuses on solving complex mobility challenges to drive innovation and competitive advantage