Engineering The Electrification

OEMs and Tier1’s face increasing pressure to accelerate EV production to meet the global demand for greener mobility solutions. With the ever-changing EV manufacturing landscape, agility is vital to establish a scalable, reliable, safe, and cost-effective design. At L&T Technology Services, end-to-end e-mobility solutions such as electric powertrain, design and development of high-voltage battery management system, and applications for power electronics are taking center stage.

Our wide range of e-powertrain systems, technologies, and solutions for varied applications and vehicle platforms: from EV to HEV to PHEV, helping customers get ahead in the e-mobility race. With hands-on experience in power electronics, software development, and state-of-the-art lab for powertrain component testing, we help customers reduce costs and accelerate the EV development journey.

- How do we simulate the expected vehicle level performance and define correct sub-system specifications with accuracy?

- How do we develop a lightweight but still cost-competitive design?

- How do we improvise power electronic system efficiencies?

- How do we “Design for Safety”?

- How do we validate the system level performance with actual parts in different drive scenarios?

Connect with our EV experts today!

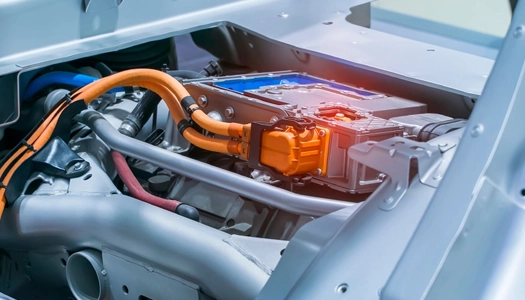

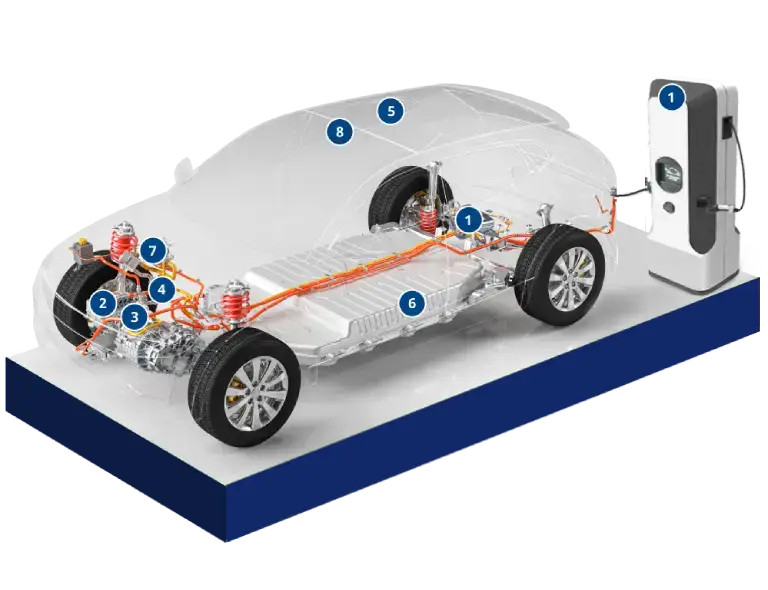

Architecting E-Powertrain

ON BOARD AND DC FAST GRID CHARGER

Achieve higher power density and efficiency with modular & scalable bi-directional Charging Solution

INVERTER/MOTOR CONTROLLER PLATFORM AND DC-DC CONVERTER

Achieve higher power density and efficiency through optimized compact unit.

VEHICLE CONTROL UNIT

Intelligent and robust domain controller for E-Powertrain.

INVERTER AND MOTOR CONTROL ALGORITHM

Efficiently manage vehicle functions & features with scalable control algorithms.

RAPID PROTOTYPING SIMULATION SUITE

Reduce design cycle time by 30-40% thru Simulation Suite.

BATTERY MANAGEMENT SYSTEMS

Enhance performance, safety and reliability thru custom-built BMS.

POWER DISTRIBUTION UNIT

Efficiently manage power distribution with “Smart Junction Box” solution.

TEST AUTOMATION FRAMEWORK

Improve validation and faster time to market by Test Automation.

ON BOARD AND DC FAST GRID CHARGER

Achieve higher power density and efficiency with modular & scalable bi-directional Charging Solution

INVERTER/MOTOR CONTROLLER PLATFORM AND DC-DC CONVERTER

Achieve higher power density and efficiency through optimized compact unit.

VEHICLE CONTROL UNIT

Intelligent and robust domain controller for E-Powertrain.

INVERTER AND MOTOR CONTROL ALGORITHM

Efficiently manage vehicle functions & features with scalable control algorithms.

RAPID PROTOTYPING SIMULATION SUITE

Reduce design cycle time by 30-40% thru Simulation Suite.

BATTERY MANAGEMENT SYSTEMS

Enhance performance, safety and reliability thru custom-built BMS.

POWER DISTRIBUTION UNIT

Efficiently manage power distribution with “Smart Junction Box” solution.

TEST AUTOMATION FRAMEWORK

Improve validation and faster time to market by Test Automation.

ON BOARD AND DC FAST GRID CHARGER

Achieve higher power density and efficiency with modular & scalable bi-directional Charging Solution.

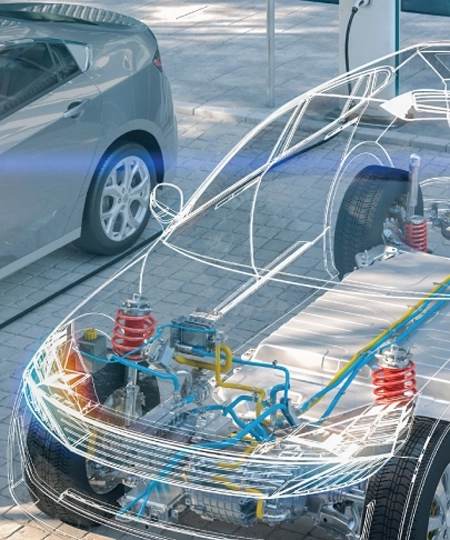

Integrated Electric Vehicle System Level Testing

LTTS Electric Vehicle Practices offers the right infrastructure setup along with domain expertise that tends to cater to a wide range of testing and validation needs, helping OEMs and Tier1s to accelerate the development of electric vehicle across the value chain.

Electric Vehicle Lab

LTTS have developed and built a one-of-a-kind Electric Vehicle (EV) testing lab at our Bangalore delivery center to perform electric vehicle component testing. This state-of-the-art lab provides various types of electric powertrain testing such as performance testing, endurance testing, and functional testing of e-Motors, Inverters, DC-DC Converters, Battery, and E-Chargers.