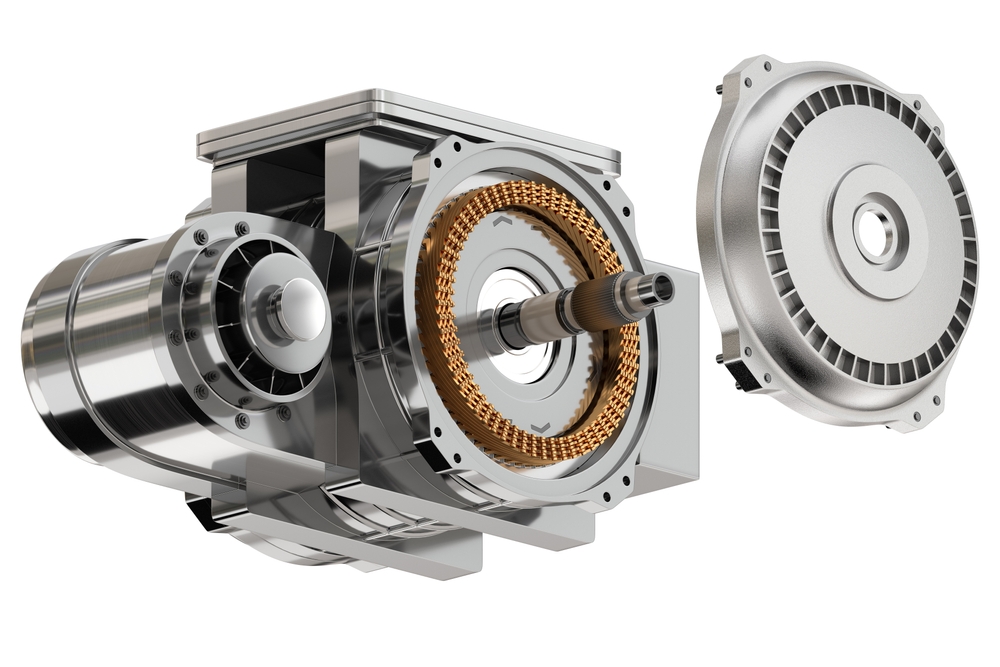

Drives & Motors

Process control, energy conservation, smooth deployment of products and services, and seamless operations are critical for enterprises as they transition to Industry 4.0. Globally, enterprises that leverage electrical motors are increasing process automation and implementing international motor efficiency standards to improve their production efficiency and capabilities while maintaining the tenets of sustainability.

The substantial rise in industrial automation is leading companies to utilize next generation drives for compact, flexible system that are easy to control, and have higher efficiency, better safety, and modular architecture. This has led to a substantial growth of the drives and motors market with experts forecasting it to reach $32.2 billion by 2027, growing at a CAGR of 6.54%.

Our Services

At LTTS, we offer a wide range of services from end-to-end design, sustenance, testing & certification, and digital services globally. Our service offerings are modeled according to a comprehensive approach to maintain the competitive edge for enterprises that holistically propels the industry forward.

Design

- Mechanical, Electrical & Electronics Design

- Magnetic Design, Model Based Development

- Functional Safety

- HMI Development

- Firmware application development

- RTOS & Driver development

- Protocol development

- Modular design & development of Inverters

- CFD & FEA Simulations, Signal integrity simulation

- Test Automation pre-compliance

- Rapid Prototyping and mass manufacturing support

- Signal Integrity

Sustenance

- Component & Obsolescence Management

- Sourcing & Should Costing

- Product Benchmarking

- Reverse Engineering

- VAVE for Drives, Motors & controllers

- Reliability and ROHS compliance

- Field Failure Analysis (RCA)

- Product Localization

- 2D/ 3D design modification work

Testing & Certification

- Qualification Testing

- Recertification of Legacy equipment

- Pre-compliance Testing

- Reliability Testing (HALT/ HAST)

- IGBT Power Cycling Test

- Characterization of Power Component

- Thermal & Environmental Testing

- Mechanical Qualification Testing | Material Testing

- Motor Control Algorithm F/W Testing

- UL/ CE safety related design verification

- DFMEA | Stress & Worst-case analysis (SWCA)

- MTBF | Six Sigma

- Functional Safety – FIT (IEC61508) | SIL Assessment

- Product Certification- UL & IEC 61800-5

- IGBT Power Cycling Test

- Characterization of Power Component

- Thermal & Environmental Testing

- Mechanical Qualification Testing | Material Testing

- Motor Control Algorithm F/W Testing

- UL/ CE safety related design verification

- Test Automation | EOL

Digital

- Predictive & Perspective Analytics

- Real-Time Performance Monitoring

- Cloudification | Automation

- Sensorization

- Cyber Security

- Web Development

The LTTS Edge

Our years of accumulation has led to an extensive repository of knowledge of drives and motors. This has enabled us to solve some of the most critical challenges that industries are faced with. LTTS helps several leading global enterprises achieve business success by leveraging:

- Infrastructure capacity including Low & Medium Power drive design capabilities, dedicated 4500 sq. ft. power lab of 250KVA capacity, full load testing for up to 100kW drives, and inhouse EMC test lab setup

- 5500+ man-years experience in electrical, drives, and power (EDP), co-authored over 120 patents in power drives and machineries, and testing for up to 690V drives

- Inhouse platform & framework, engineering domain expertise, and functional safety experts

- Support for on-field failure analysis & solution

- In-house lab infrastructure for product testing and development