Instrumentation

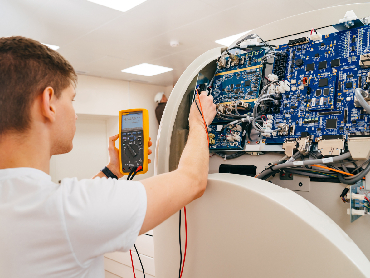

At LTTS, our offerings include end-to-end services across design, development, and maintenance of various test and measurement instruments. Our goal is to orchestrate a holistic overhaul of the existing industrial approach toward measurement devices, helping global enterprises address their most pressing test and measurement needs

Our Focus Areas

Measuring Devices

- Intelligent transmitter

- Intrinsic safe sensor

- Flame, conductivity,temperature, and pressure sensors

- Flow recorder

- Power measurement devices

Analytical Instruments

- Gas analyzer

- Gas chromatograph

- TOC analyzer

- Water quality analyzer

- Gauge analyzer

Monitoring Equipment

- Gateway products

- Alarm management controller

- Fieldbus controller

- Flow computer

- Sub-station monitoring instrument

Test Lab Equipment

- Logic analyzers

- Oscilloscope

- Data acquisition systems

- Spectrum analyzer

- Signal generator

Holistic Enterprise Instrumentation Services

NPD - Hardware & Firmware

- Analog and mixed signal design

- RF /Wireless design

- Industrial protocols expertise

- RTOS and Linux based firmware

- Intrinsic safe design

Mechanical Design

- 2D/3D Design & modelling

- ECN/ ECR

- Benchmarking

- Fixture and Tool Design

- Industrial Design

Test Automation

- In-house test accelerator framework to reduce test cycle

- Design of Test fixtures, Bed of nails

- NI LabVIEW based test automation

- Stress testing and Regression testing

Sensorization

- Sensorization and loT Connectivity

- Edge Processing, Embedded Al

- Machine sensor Data Monitoring,

- Predictive and Preventative Analytics

- In-house Lot and Engineering Analytics CoE

Digital

- IoT, Cloud

- Analytics, Predictive Maintenance

- Applications/Software Development

- Software Testing and Validation

- Cyber Security

Software Development

- Web-based software development

- UI/ Graphics development

- Responsive UI development

- Web server porting on devices

- Mobile application development

Product Maintenance

- Obsolescence management

- Sustenance engineering

- Value engineering

- Documentation support

- Drawing management

- Verification and Validation

Back Office Support

- Supply Chain Support

- L1, L2, L3 Support

- Bid Management

- Product Configuration

- Product Training

NeXSens: The LTTS Sensor Lab for Next-Gen Sensorization

At LTTS, we constantly push the boundaries of innovation to offer the best that next-gen technology has to offer. Our sensorization lab NeXSens carries this mantle forward with a range of innovative sensors based on use-case-specific requirements.

Spilling the Secrets

At the LTTS instrumentation labs, our quest is to continually offer innovative and next-gen equipment that can keep our clients firmly aligned with the digital age and always a step ahead. To achieve our goals, we bank on our strengths that include:

- End-to-end product development expertise

- Dedicated sensor lab - NeXSens

- High-speed designs for rapid deployment

- Industrial connectivity protocols for maximum compatibility