Plant Control Mobility Solutions (PCMS)

Intelligent asset utilization could help reduce production costs significantly – however, this relies on a robust technology framework that combines data processing with insights generation. It’s essential to adopt advanced recipe management models and efficient switchovers in the manufacturing line. This would boost asset utilization rates and minimize production losses, leading to a jump in larger ROI metrics.

Current systems often struggle with seamless data availability and this delays/impedes decision-making. Critical events that require immediate intervention or signals suggesting long-term impacts should not be ignored. At LTTS, we believe remote monitoring and mobile solutions are key to empowering plant managers, enabling smart, timely actions on the floor.

We help our customers track a range of recipe and formula parameters from mobile devices, communicating relevant data and best-fit recommendations to the shop floor. We connect plant instruments and control systems (PLC, SCADA, Historian) to the cloud via LTTS UBIQWeiseTM, our proprietary IoT platform for industry-grade cloud access.

An Android app allows users to view and control various process parameters, with event alerts and vitals tracking to gain the following benefits:

- Rapid product changeover

- Multi-plant utility consumption benchmarking

- Mobile access to critical plant floor data

- Consistent device health monitoring

- Robust warehouse management

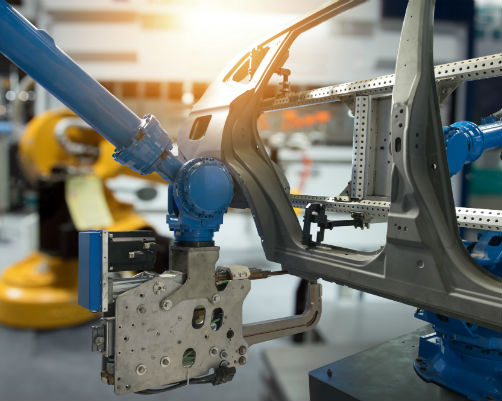

RE-IMAGINING MANUFACTURING TO DELIVER EXCELLENCE

We expedited electric vehicles manufacturing, via automated, cost-optimized operations