Material Test Center

The industrial sector is a complex ecosystem with material testing at its core. Ensuring consistent quality, navigating accurate failure investigations, and making effective material selection are all integral parts of this intricate process. The challenge lies not just in dealing with a variety of materials like plastics and composites, but also in understanding their behavior under different environmental conditions.

Consider industries such as Aerospace, Automotive, Medical, and FMCG. Here, material testing goes beyond assessing product durability—it plays a crucial role in minimizing risks. Even a minor flaw could have serious repercussions, leading to product recalls, brand damage, and potential legal complications.

In the face of rapid technological advancements and tightening regulatory demands, innovation while maintaining top-notch quality standards is essential. This positions material testing as not just a necessity, but a key to survival and success.

The industrial sector is a complex ecosystem with material testing at its core. Ensuring consistent quality, navigating accurate failure investigations, and making effective material selection are all integral parts of this intricate process. The challenge lies not just in dealing with a variety of materials like plastics and composites, but also in understanding their behavior under different environmental conditions. This is where L&T Technology Services’ Material Testing Laboratory comes into play. We’re not just service providers—we’re your partners in overcoming these challenges. Our comprehensive suite of raw material testing services is meticulously designed to navigate these complexities with unerring precision.

Integrated Testing Portfolio

Evaluates materials’ physical properties through Density and Flexural testing, ensuring they surpass industry standards to enhance product performance and reliability.

Assesses materials' strength and durability via Impact testing, crucial for ensuring product safety and longevity under various stress conditions.

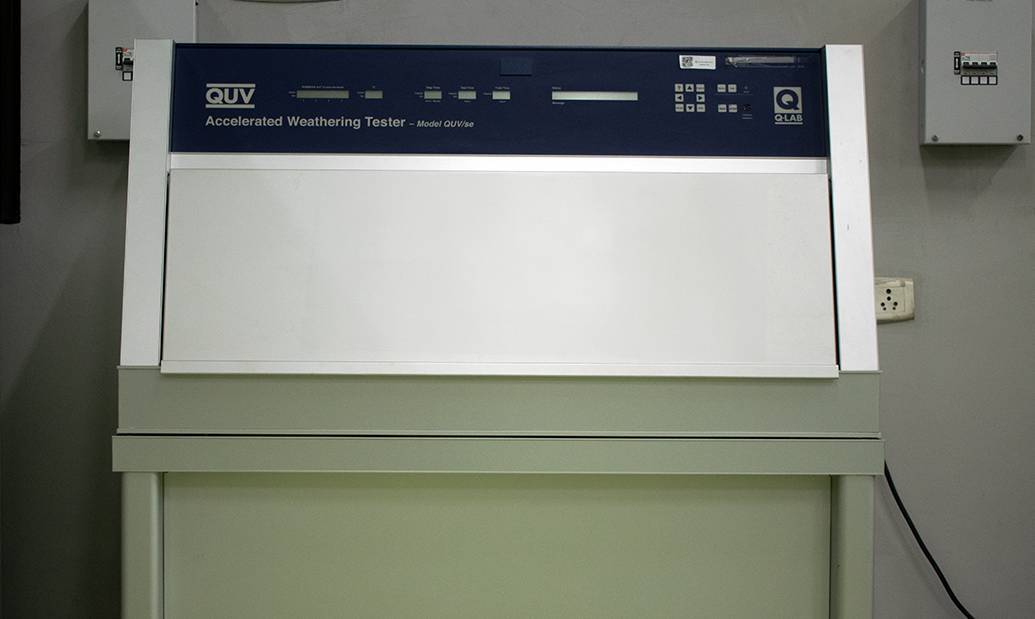

Utilizing UV, Xenon arc and Heat Ageing Chamber in Testing, we determine a material's resistance to weathering, contributing to the overall durability and longevity of the final product.

With HDT Testing, we characterize and verify the heat resistance of plastic materials. This helps in choosing materials that can withstand extreme thermal conditions, enhancing product safety and durability.

MFR Testing helps us assess whether materials are processed effectively with minimal degradation, ensuring smooth manufacturing processes and superior end products.

Customized In-House Injection Molding

We have the unique advantage of preparing our test specimens within our own facility, strictly adhering to ISO/ASTM standards.

Specialized Conditioning Chambers

Our specimens aren't just prepared; they mature in dedicated chambers before they're ready for further processing.

Innovative Dehumidified Hopper Dryer

We take drying to the next level with our hopper dryer that allows simultaneous drying of raw materials during molding.

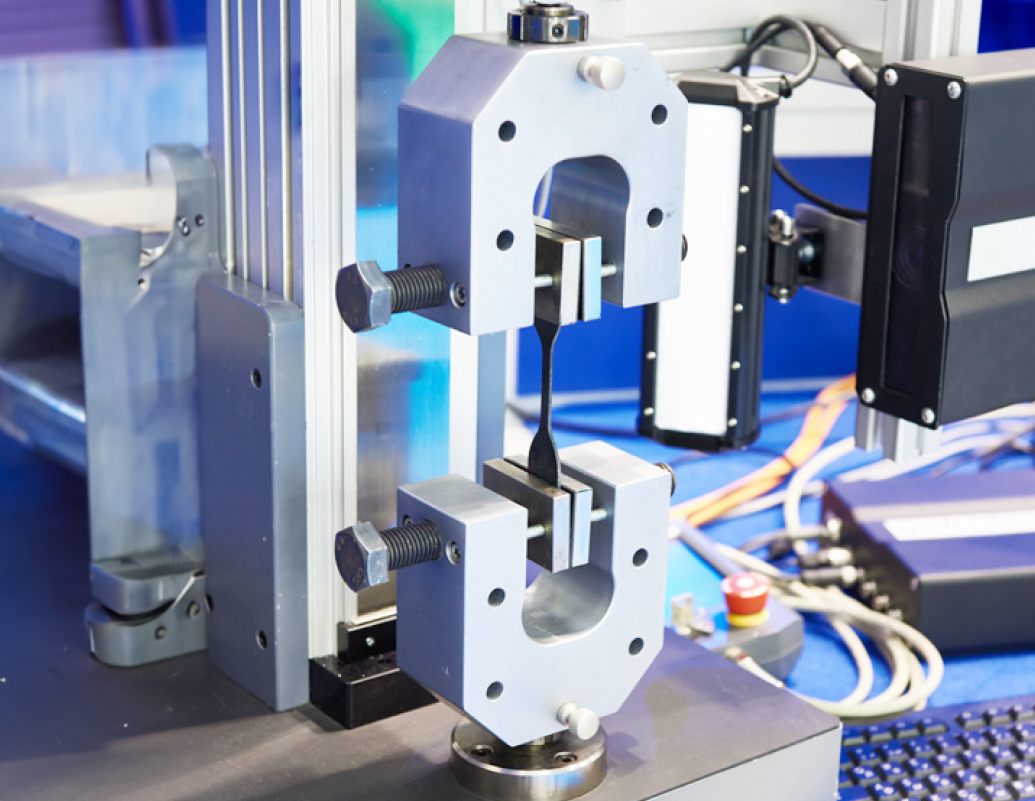

Precision via Extensometers

For the most accurate tensile elongation measurements, we employ extensometers.

Controlled Environment for Accurate Results

We maintain rigorous temperature and humidity controls in our testing area to ensure the accuracy of our results.

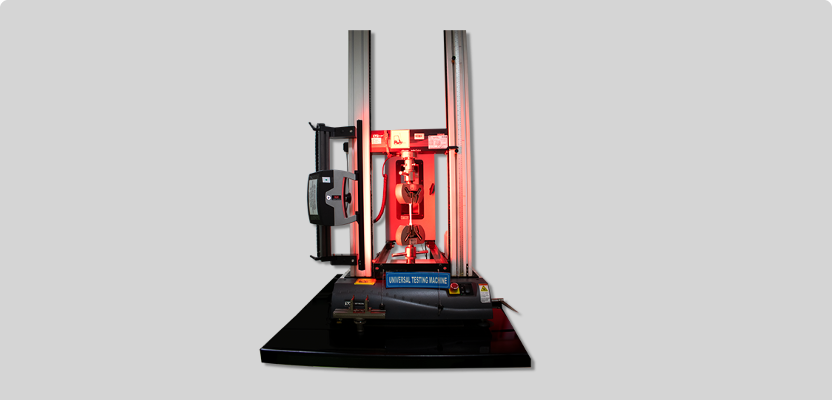

Universal Testing Machine

Our capabilities extend from extreme cold (-70°C) to intense heat (250°C), thanks to an with integrated chamber fueled by liquid nitrogen.