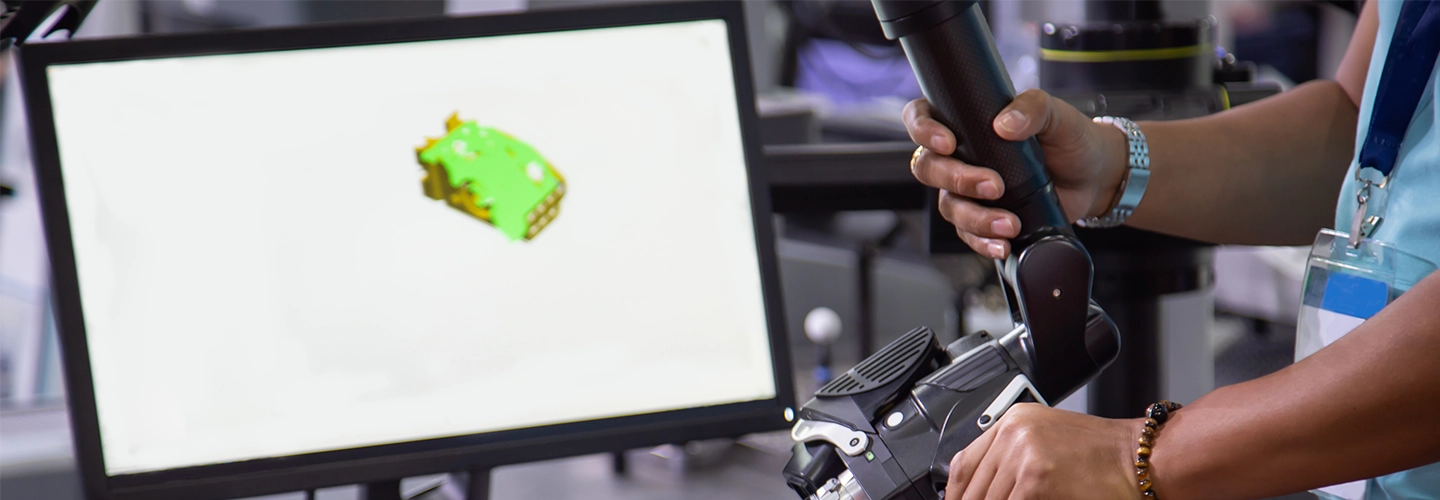

Amidst a dynamic medical devices manufacturing ecosystem, our innovative Computed Tomography (CT) solutions address key challenges while ensuring speed, reliability, and cost-effectiveness.

We enable:

- Dimensional Inspections: Across large, intricate, and delicate components where speed and accuracy are vital;

- Optimized Analysis Time: Accelerating part-to-print analysis, part-to-part comparisons, and reverse engineering initiatives;

- Geometry Analysis: For part geometry delivering insights and necessary adjustments, including wall thickness, draft, and profiles;

- Mold Tool Corrections: Enabling swift corrections and evaluation of mold tool health through precise part measurements;

- Failure Investigations: Toward minimizing the need for multiple iterations to identify root causes, especially for internal structures; and

- Destructive Testing: Minimizing time and costs associated with destructive testing to uncover manufacturing defects like voids, inclusions, cracks, and weld lines.

Why Choose LTTS’ CT Solutions?

Our advanced CT scanners facilitate non-destructive inspection of workpieces, allowing for a comprehensive analysis and comparison of both dimensional and geometrical features with unmatched speed and accuracy.

Unlock the potential of your manufacturing processes with our next-gen CT solutions.

Download the Flyer now!